|

|

|

| |

|

|

|

|

|

|

- (1)

- (1)

- (1)

- (1)

- (2)

- (1)

- (1)

- (1)

- (3)

- (9)

- (1)

- (3)

- (10)

- (1)

- (1)

- (2)

|

|

| |

|

|

Build Your Online Product Catalogs?

| Product Name: |

Disposable Vacuum Blood Collection Tube Full Autom

|

| Supply Ability: |

1 |

| Related proudcts |

|

| Specifications |

OEM |

| Price Term: |

T/T |

| Port of loading: |

guangzhou |

| Minimum Order |

1 piece |

| Unit Price: |

according to demand |

|

The Vacuum blood collection tube fully automatic assembly line is mainly used for manufacturing Non-vacuum and vacuum blood collection tubes. It connects all the steps in one automatic recycling way, greatly increase the production capacity, if of high degree of automation, fast and convenient, greatly reducing the labor cost.

Description:

1. Loading Tube:

Adding tube part is fixed by servo motor, stable running, accurate position and fast speed. Suitable for size 13*75/13*100mm PET tube or glass tube.

2. Spray & Filling Liquid:

Spray and Filling part adopts American imported quantitative control pump and patent nozzle, one-to-one quantitative control, good repeat-ability, precise quantity, and easy for adjust and maintain.

3.Drying:

The drying position of tubes can be adjusted based on production requirement; temperature and time is adjustable, which can completely meet with the drying requirement of vacuum blood collection tube production.

4.Adding Cap´╝?

Automatic Adding Cap part adopts servo motor for positioning; through unique adding cap device( Air adsorption+ Rubber fix) to ensure the caps will not be dropped off or left adding during production process.

5.Vacuum Pressure Capping´╝?

Vacuum Pressure capping part adopts adopts the imported vacuum pump and high precision pressure sensor, small noise, no pollution and fast speed; accurate quantity and the vacuum quantity can be adjusted based on production requirement.

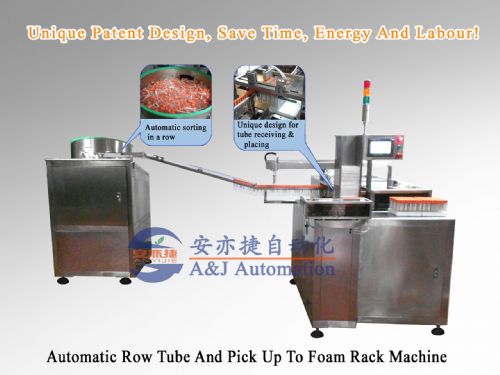

6.Pick Up To The Foam Rack´╝?

Automatic putting in rack part fixes position by servo motor.It can automatically put the finished products into white rack with high accuracy and fast speed,greatly improving the production efficiency.Can be designed as Squre permutation or

Rectangle mismatch permutation.

7.Online Intelligent light inspection system

With optional intelligent inspection system, inspect finished product and remove the unqualified products.

8.Place tubes on the diagonal foam rack:

also can prefer to place tubes on the diagonal foam rack, which will re |

| Company: |

Guangzhou A & J Automation Equipment Co., LTD

|

| Contact: |

Mr. Sam chang |

| Address: |

No.8 Huaying Road, Jichang west Road, Baiyun District, Guangzhou |

| Postcode: |

510440 |

| Tel: |

862062157515 |

| Fax: |

862063243482 |

| E-mail: |

|

|

|